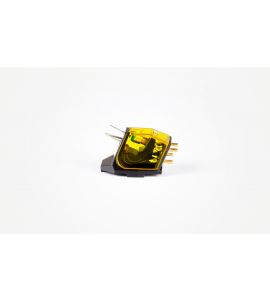

Rega Ania PRO (MC) Galviņa

Rega Ania Pro (MC) galviņā ir izmantota mūsu uzlabotā "Vital" profila dimanta adata. Šis profils ir speciāli konstruēts, lai no vinila virsmas iegūtu pēc iespējas vairāk nianšu detaļu. Ania Pro nodrošina precīzu basu, siltu vidējo frekvenču diapazona un precīzu augšējo frekvenču atskaņošanu - tas viss veido labi līdzsvarotu un detalizētu skanējumu.

Ania Pro galviņa ir ievietota unikālā PPS izturīgā korpusā, tajā tiek izmantota Rega trīs punktu fiksēšanas metode. Jaunais korpuss ir aizsargāts ar CAD izstrādātu stingru aizsargvāku, tas pasargā iekšējos smalkos vadus, padarot adatas vadāmību vienlaikus pietiekami kustīgu un drošu (bez riska visu konstrukciju sabojāt). Ania galviņa ir aprīkota ar īpaši jaudīgu neodīma magnētu un spirāli, kas rūpīgi savīta kopā "dzelzs krustā". Šī visa radītā konstrukcija/miniatūrā montāža ļauj mums brīvāk izsekot vinila rievai - tas nodrošina vēl vairāk iegūtu, visai smalku nianšu un detaļu, atskaņojot jūsu iemīļoto vinilu (skaņuplati).

Ania (MC) galviņa ir īpaši saderīga ar Planar 3, Planar 6 un RP8 Regas skaņuplašu atskaņotājiem.

Listen like a PRO

Using our unique hand-wound micro coil found in the rest of the MC range, the Ania Pro is housed in a unique PPS highly rigid body, ensuring accurate construction and Rega’s three point fixing method which offers the optimum connection to the head-shell while automatically setting overhang. The new body is protected by a CAD designed, red rigid cover to protect the internal fine wires, making handling when fitting, safe and risk free.The Ania Pro features a super high-powered, neodymium magnet and a coil meticulously hand wound on to an iron micro cross. This miniature assembly allows us greater freedom to track the vinyl groove guaranteeing even more detail is extracted from the vinyl. All of these features combine to deliver a balanced and dynamic performance that will engage you with your vinyl like never before. The Ania Pro is the perfect partner for the Planar 3, Planar 6 or Planar 8 turntable and a factory fitted option is available for both Planar 6 and Planar 8. Please ask your retailer for details.

KEY FEATURES

- Vital profile nude diamond

- Aluminium tapered cantilever

- Iron micro cross assembly

- One of the worlds smallest MC generators

- Cutting edge high power Neodymium magnets

- Coil constructed from 0.018 mm fine wire

- Lifetime warranty against manufacture defects

MORE PRODUCT INFO ▼

Rega’s Moving Coil cartridge design is unique in its approach to achieving an ultra-low mass generator which is undamped (no tie wire) using a unique rhomboid pivot for the cantilever powered by a purpose designed, exclusive to Rega, Neodymium magnet system.

This type of design requires a zero-tolerance engineered cartridge body which is Rega’s area of expertise and with the Apheta 3 and Aphelion products these bodies are machined from one piece of the highest quality aluminium. This is a difficult and expensive process requiring all of Rega’s forty-four years of experience to achieve. In particular, the “zero” tolerancing of the body is required in the alignment and dimension of the pivot pad mounting hole and the magnet mechanism mounting hole relationship.

The Ania Pro body uses a unique polymer/ 40% glass combination called Polyphenylene Sulphide (PPS-Fortron). The special attributes of this material are its hardness and stability in shape and dimension post moulding, both critical for the performance of Ania. Now came the challenge. Rega designed and prototyped using SLA systems in just a few months, proving the validity of the design direction.

Now we had to design a production mould tool capable of extreme accuracy and long life. PPS is a difficult polymer to mould and requires special attention to how the mould tool operates. Couple this to an almost unmouldable complex shape of the Ania body and a very considerable challenge faced the Rega engineers and the toolmakers chosen. The toolmakers are of the highest technical skill level, using the most accurate Swiss EDM CNC machines, their regular customers being the military and medical industries, routinely working down to a micron (one thousandth of a millimetre).To achieve this intricate body shape required the most complex high pressure injection mould tool that Rega has ever designed. The tool has eight major parts, four of which must move in perfect synchronicity with each other to achieve each cartridge body. The design and manufacture of this “work of art” took an entire year to produce and was made exclusively by the most senior toolmaker requiring all his lifetime of artisanal experience.

Combine this special PPS body with its high specification stainless steel inserts, a unique rhomboid pivot system, a tried and tested high performance, diamond tipped elliptical stylus cantilever with low mass moving coil generator assembly and you have new market leading musicality, performance, speed, clarity, and detail as never before at this price.